Electronic devices with high frequency are developing nowadays, especially in wireless networks. In addition, satellite communication is growing rapidly, and information products move towards high speed and high frequency.

What is high-frequency PCB?

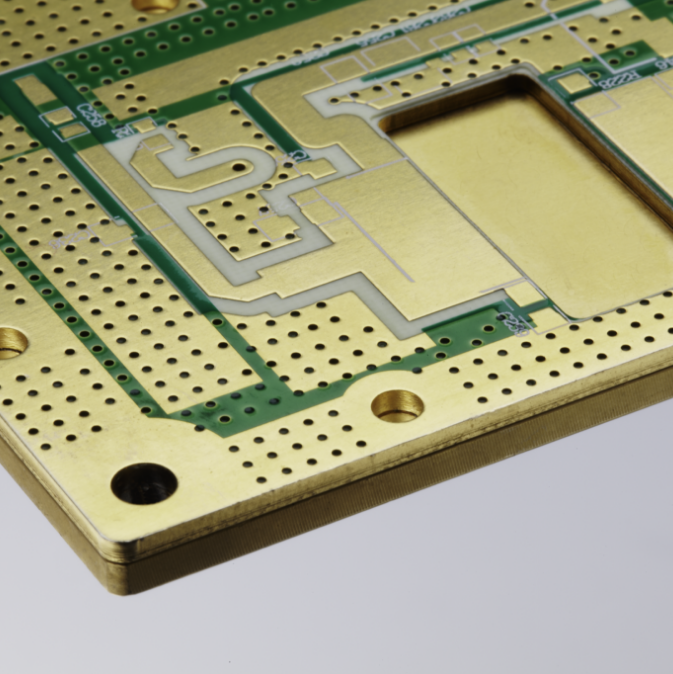

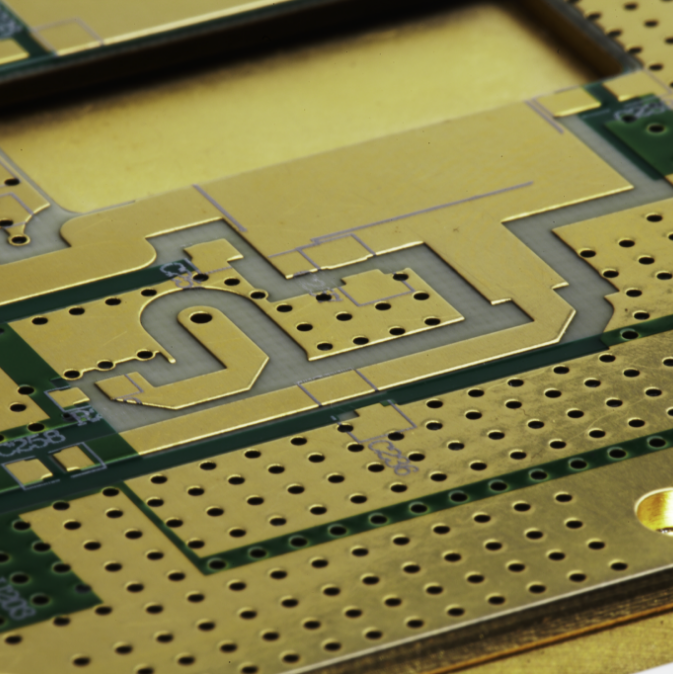

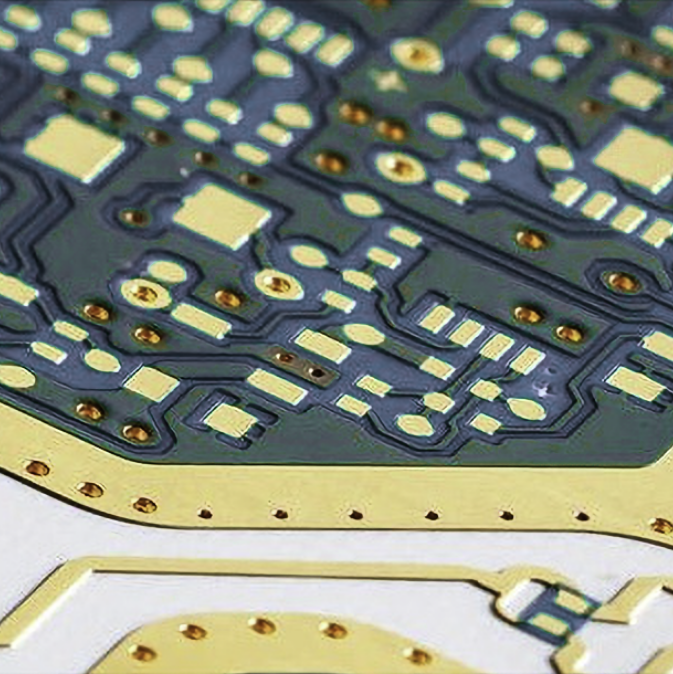

High-frequency PCBs are often needed while developing new high-frequency products, such as satellite systems, radio frequency, microwave, mobile telephone base stations, etc. These communication products usually use high-frequency substrates when designing the PCB.

It has a frequency range of 500MHz to 2GHz, perfect for high-speed designs. Higher transmission frequencies can also give faster signal flow rates, which are critical in today’s increasingly sophisticated electronic switches and other components.