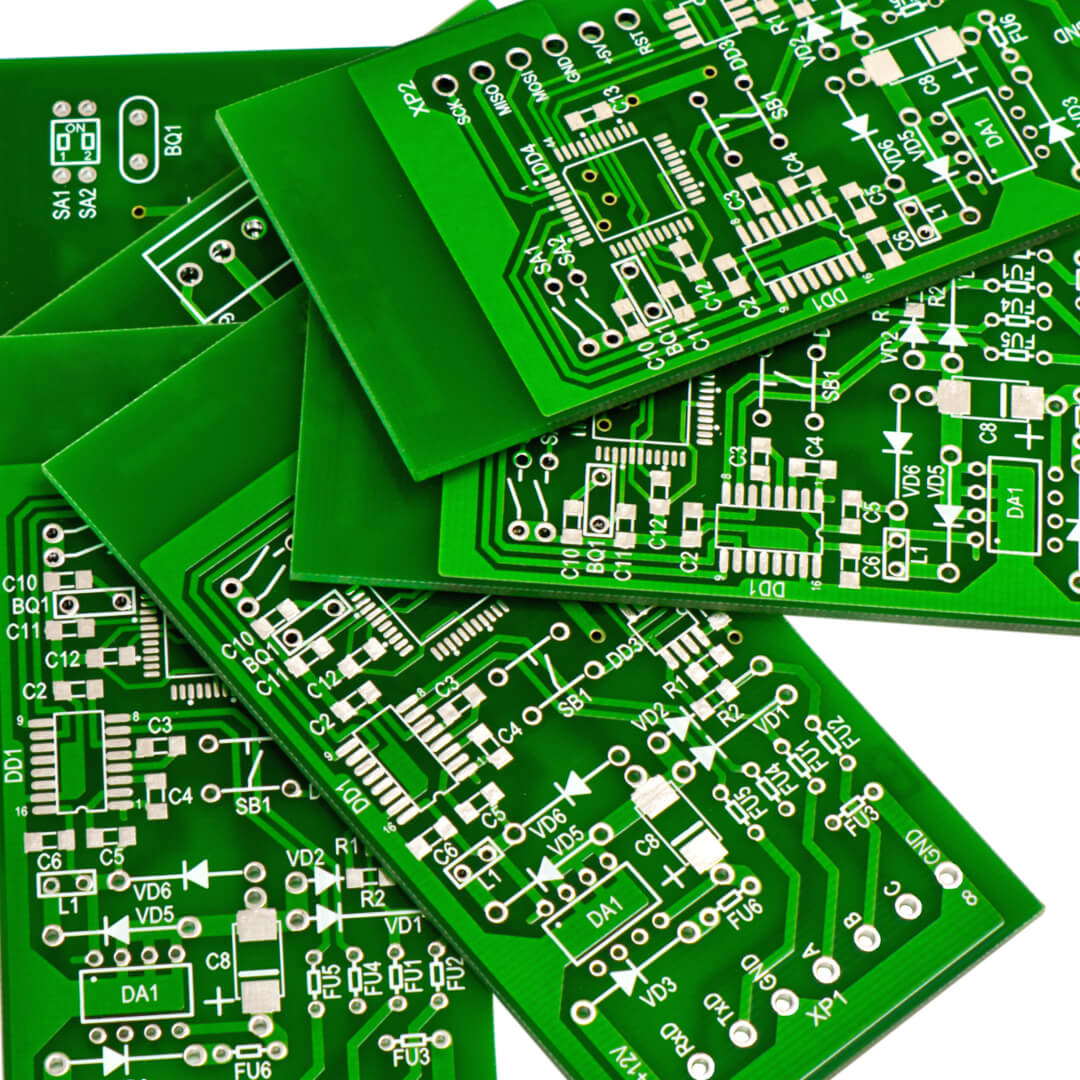

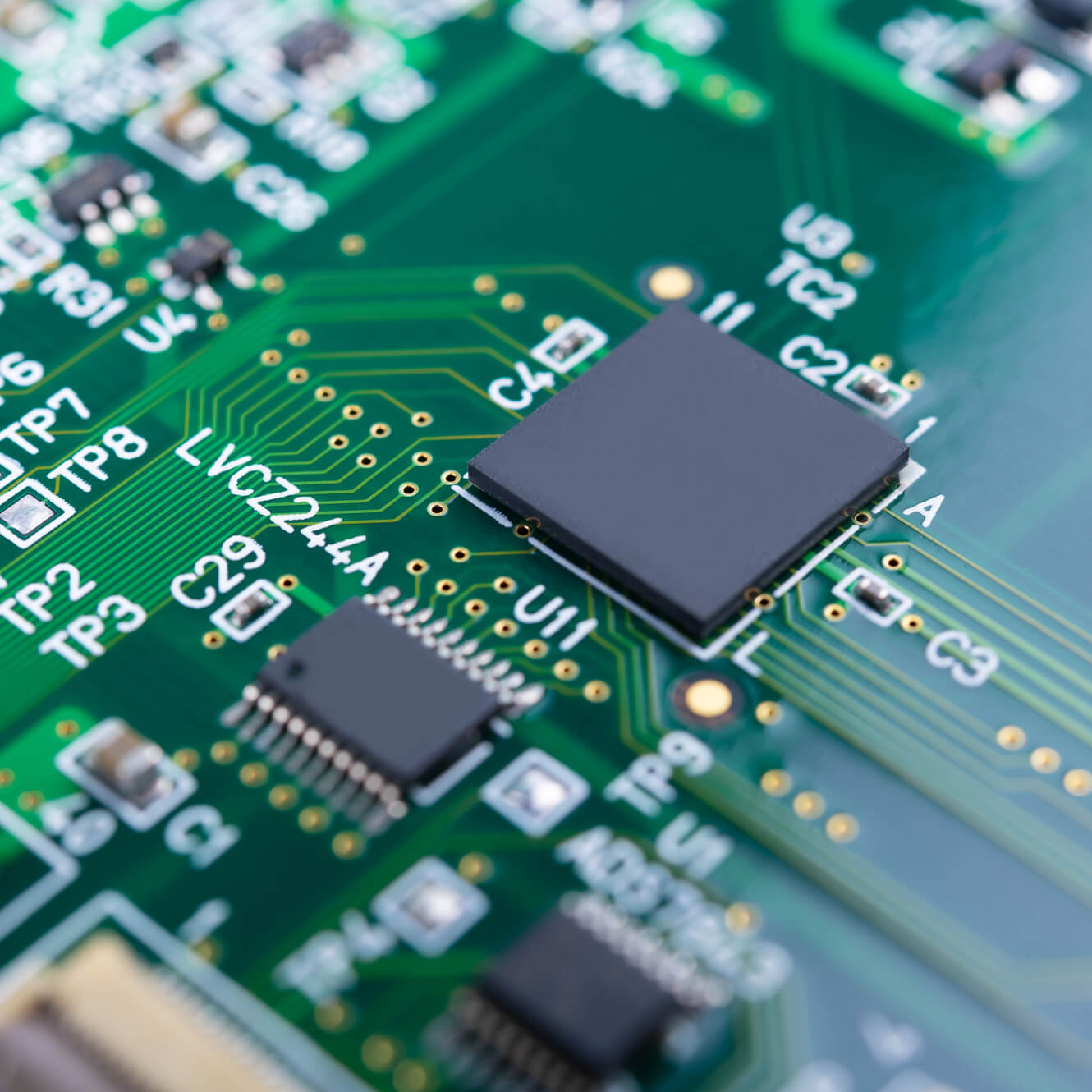

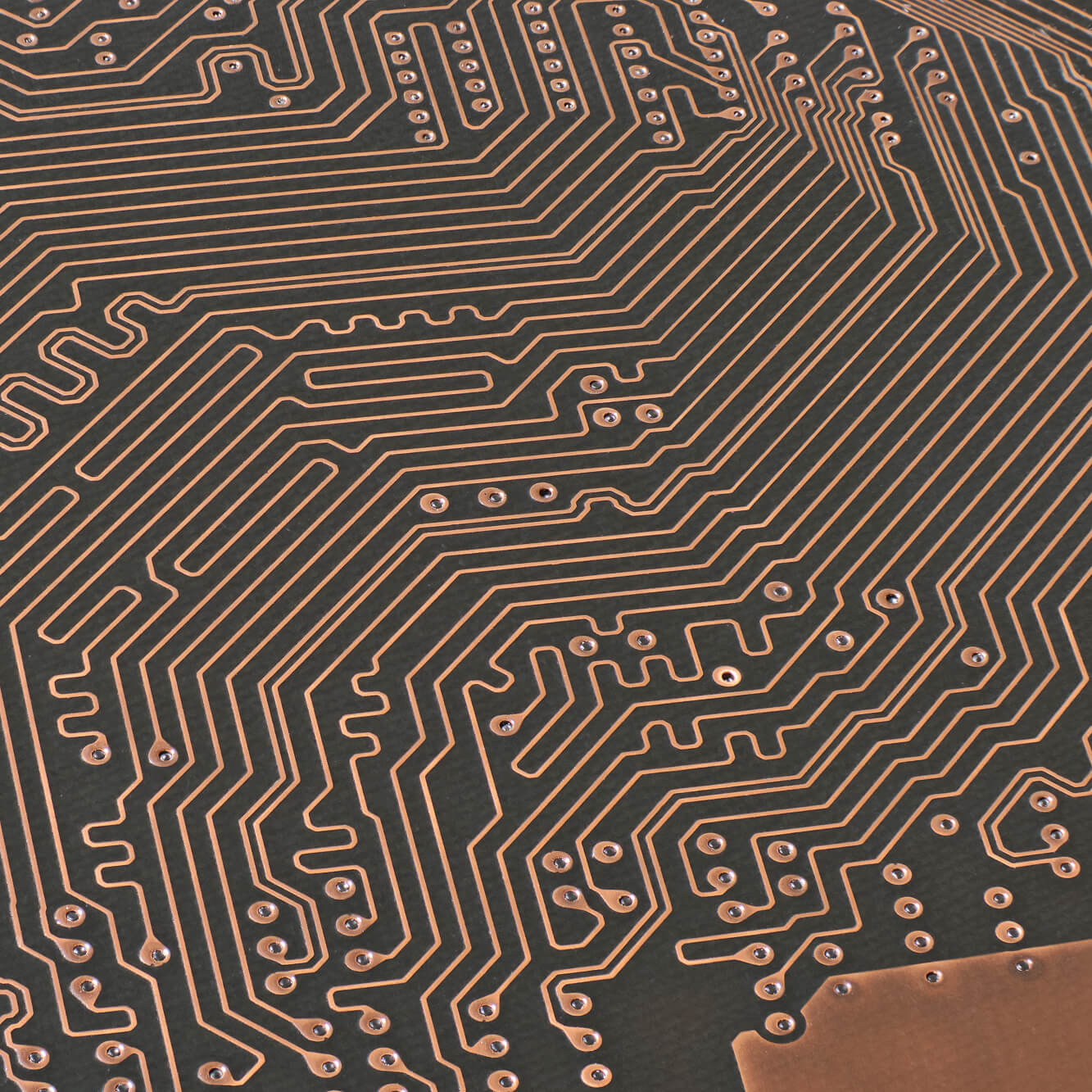

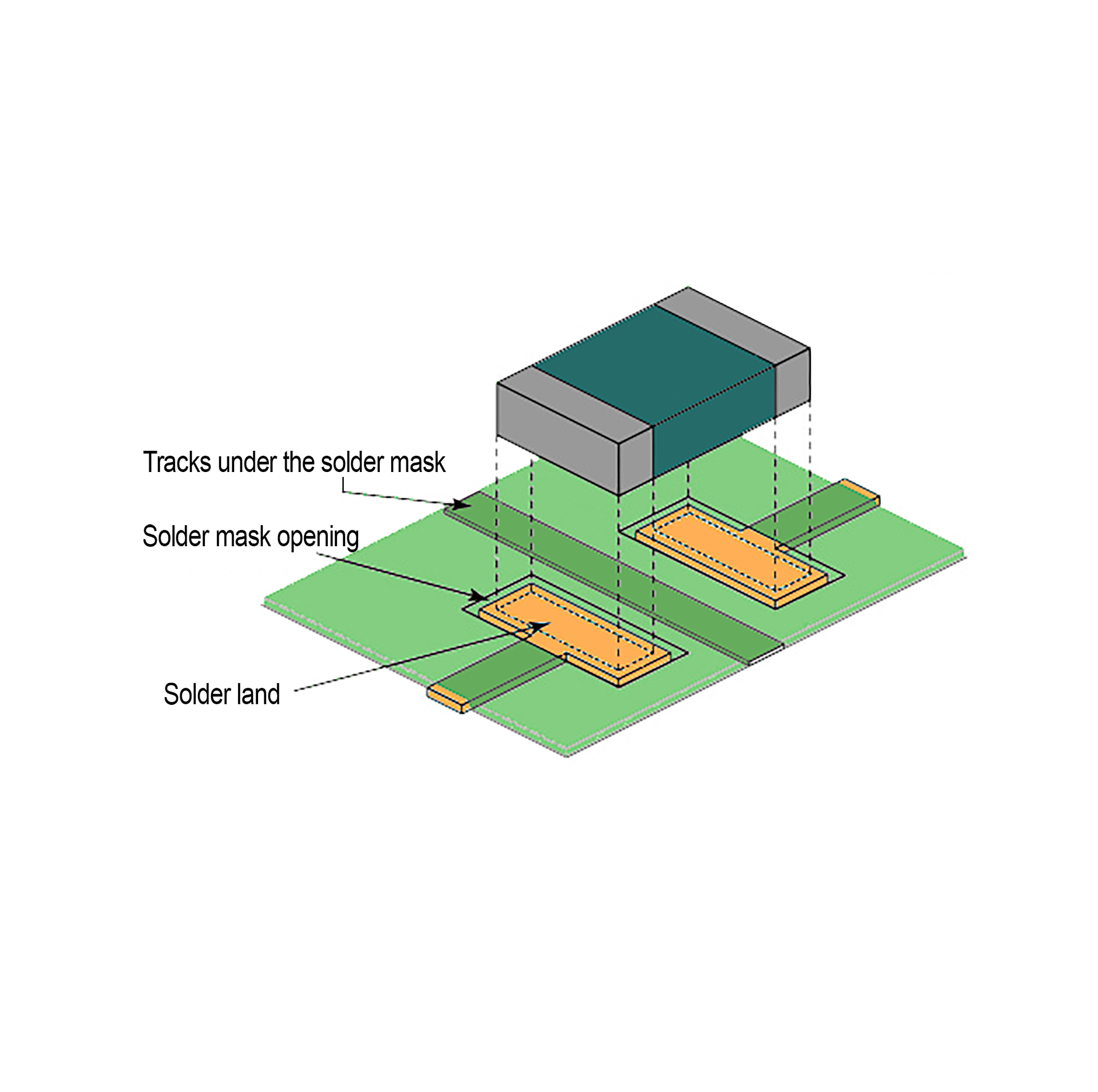

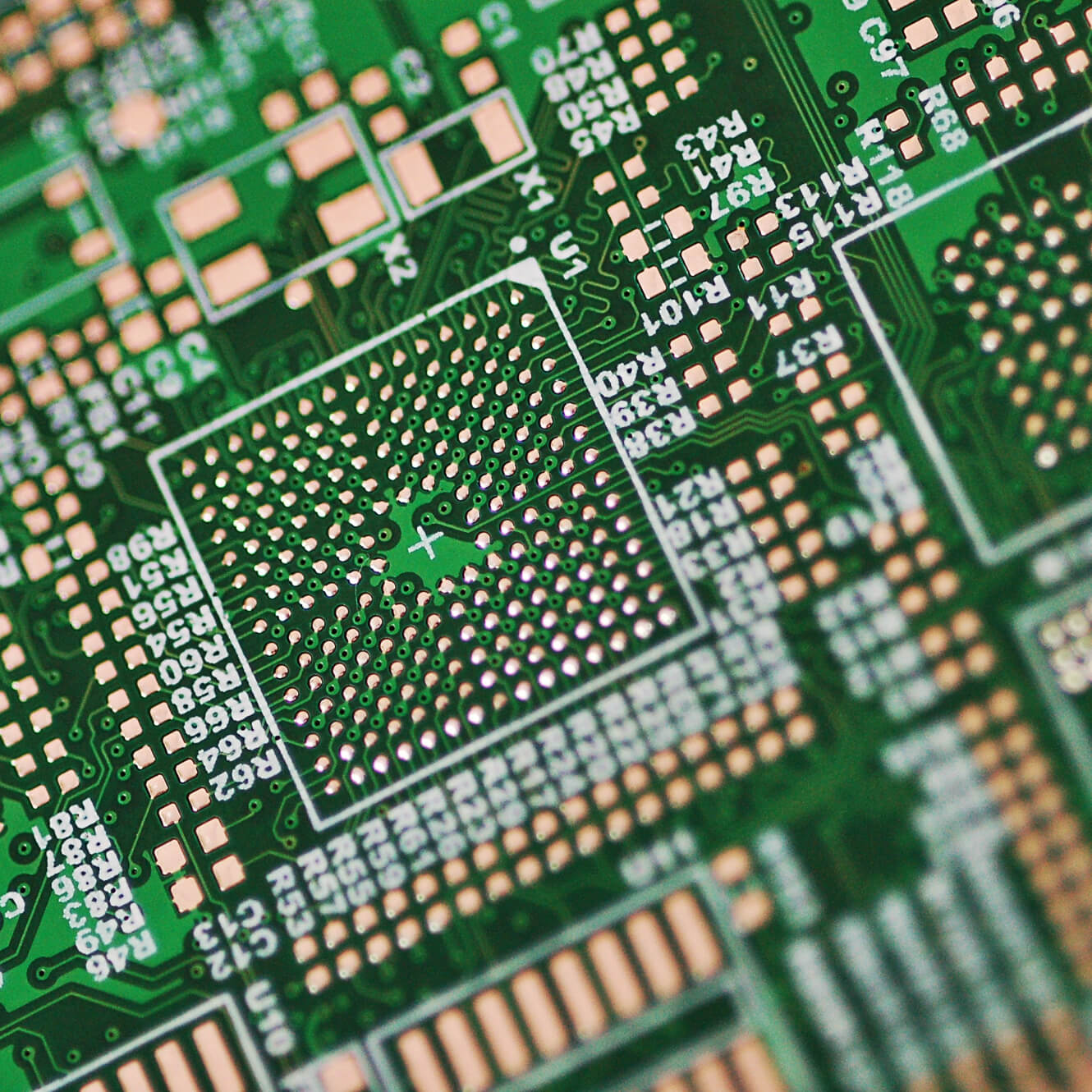

Printed circuit boards (PCBs) are the critical elements in the electronic devices since nearly 100 years. The PCB base is a non-conductive material with copper tracks printed and etched. Electronic components are mounted on the board, and the tracks connect the parts to form a working circuit.

What's a PCB?

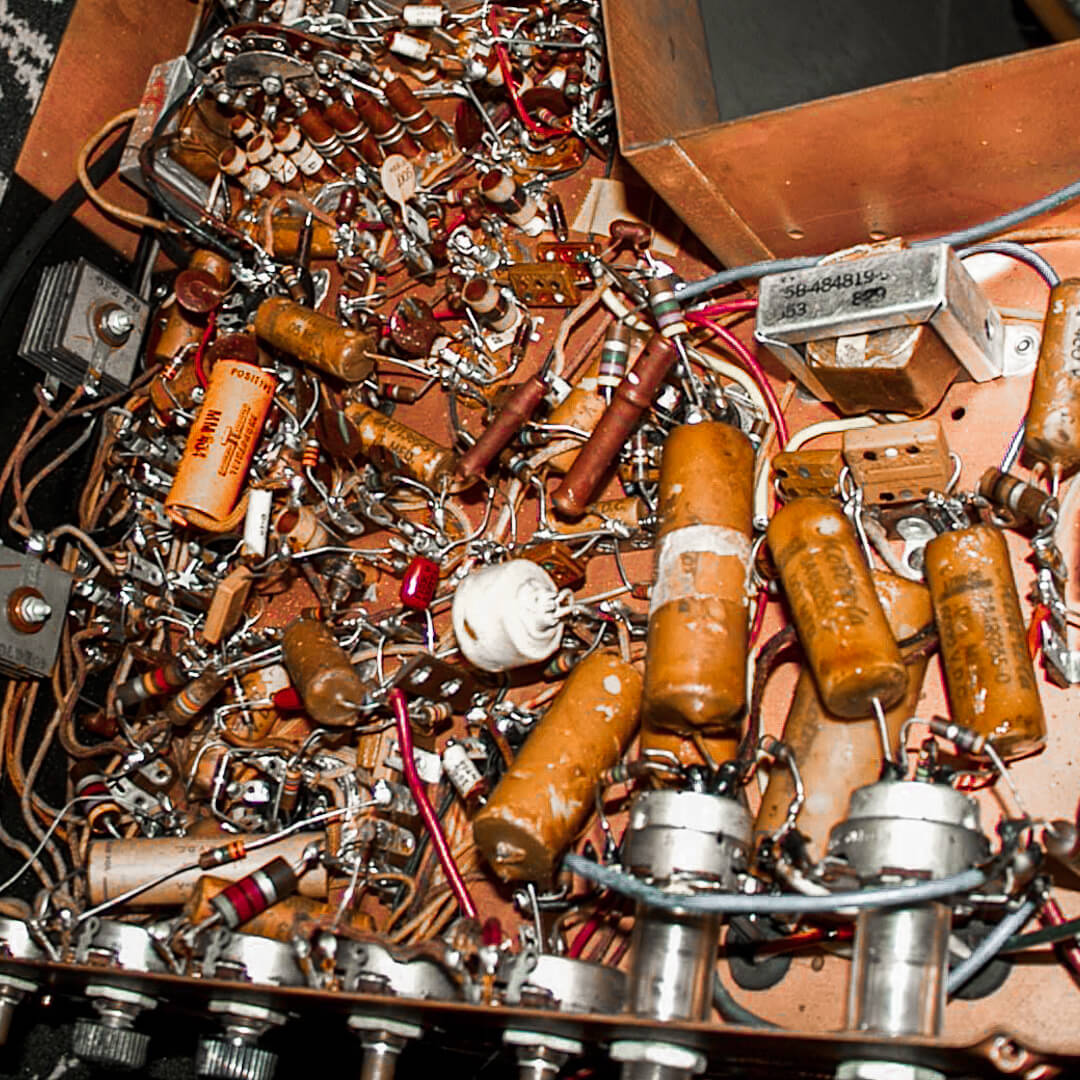

The printed circuit board is the most common name but may also be called “printed wiring boards” or just “the PCB”. Before the development of the PCB, circuits were constructed through a complicated process of point-to-point wiring. This led to frequent failures at wire junctions and short circuits when wire insulation began to age and crack.

A significant advance was the development of wire wrapping, where a small gauge wire is literally wrapped around a post at each connection point, creating a gas-tight connection which is highly durable and easily changeable. More about PCB history can be found in our blog section.

As electronics moved from vacuum tubes and relays to chip and integrated circuits, the size and cost of electronic components began to decrease. Electronics became more common in consumer goods, and the pressure to reduce electronic product size and production costs forced manufacturers to look for better solutions.